Discover how cellulase polishing enzymes, pH-neutral enzymes, and peroxide decomposition enzymes revolutionize sustainable denim washing processes. Reduce environmental impact while enhancing fabric quality.

.png)

The Evolution of Enzyme Technology in Sustainable Denim Manufacturing

The denim industry continues to pioneer innovations in fabric treatment and garment washing processes. With escalating global demand for eco-friendly textile production, enzymatic denim finishing has emerged as a transformative solution. Specialized enzymes – including cellulase polishing enzymes, pH-neutral enzymes, and peroxide decomposition enzymes – now critically enhance denim aesthetics while reducing environmental footprints. This comprehensive analysis examines these enzymatic technologies, detailing their mechanisms, sustainability benefits, and impact on denim finishing.

.png)

Enzymatic Processing Fundamentals in Denim Fabric Treatment

Cellulase enzymes catalyze controlled hydrolysis of cellulose fibers under precise temperature (typically 45-55°C) and pH conditions (acidic or neutral). This biochemical action gently degrades surface fibrils, enabling:

- Progressive indigo dye removal through controlled fiber erosion

- Elimination of surface fuzz (pilling reduction)

- Enhanced drape characteristics and water absorption

- Preservation of fabric tensile strength

Unlike abrasive stone washing techniques that damage fabric integrity, enzymatic washing achieves authentic vintage appearance ("wear-through effect") while maintaining garment durability. The process significantly reduces water consumption and eliminates pumice stone particulate pollution.

Cellulase Polishing Enzymes: Precision Surface Enhancement

Denim polishing enzymes (specifically cellulase formulations) systematically hydrolyze surface microfibrils to elevate fabric quality. These biological catalysts deliver:

- Mechanical Action Reduction

Replaces destructive sandblasting denim techniques and stone tumbling with biochemical finishing, minimizing fiber damage and textile waste generation.

- Controlled Aesthetic Development

Adjusting enzyme concentration, processing duration, and mechanical action enables precise calibration of vintage fading effects and softness gradients.

- Quality Superiority

Finished garments exhibit uniform color fading, enhanced surface smoothness, and reduced pilling tendency.

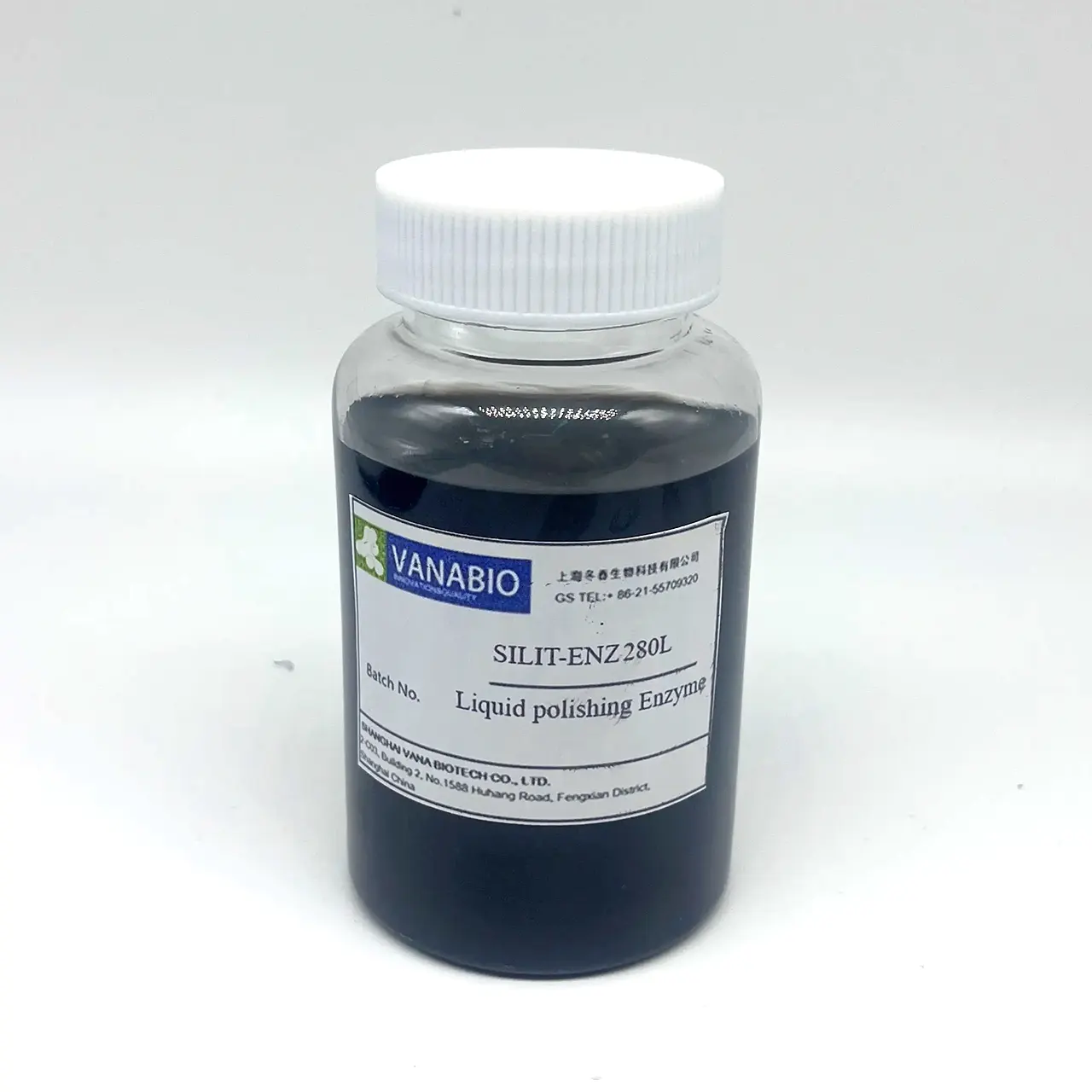

Industrial Implementation Case:

Our polishing enzyme SILIT-EN 280L utilizes non-pathogenic bacterial strains cultivated through liquid fermentation technology, followed by membrane filtration and ultra-concentration processes. This high-activity cellulase delivers authentic stone-wash appearance without fabric degradation.

pH-Neutral Enzymes: Optimized Process Stability

Neutral cellulase enzymes operate optimally at circumneutral pH levels (6.0-8.0), providing critical advantages in denim finishing:

- pH Homeostasis Maintenance

Prevents cellulose degradation fluctuations during extended processing cycles

- Co-Substrate Elimination

Degrades residual processing oils and organic contaminants, reducing synthetic surfactant requirements

- Textile Effluent Impact Reduction

Diminishes alkaline/acidic chemical loads in wastewater streams

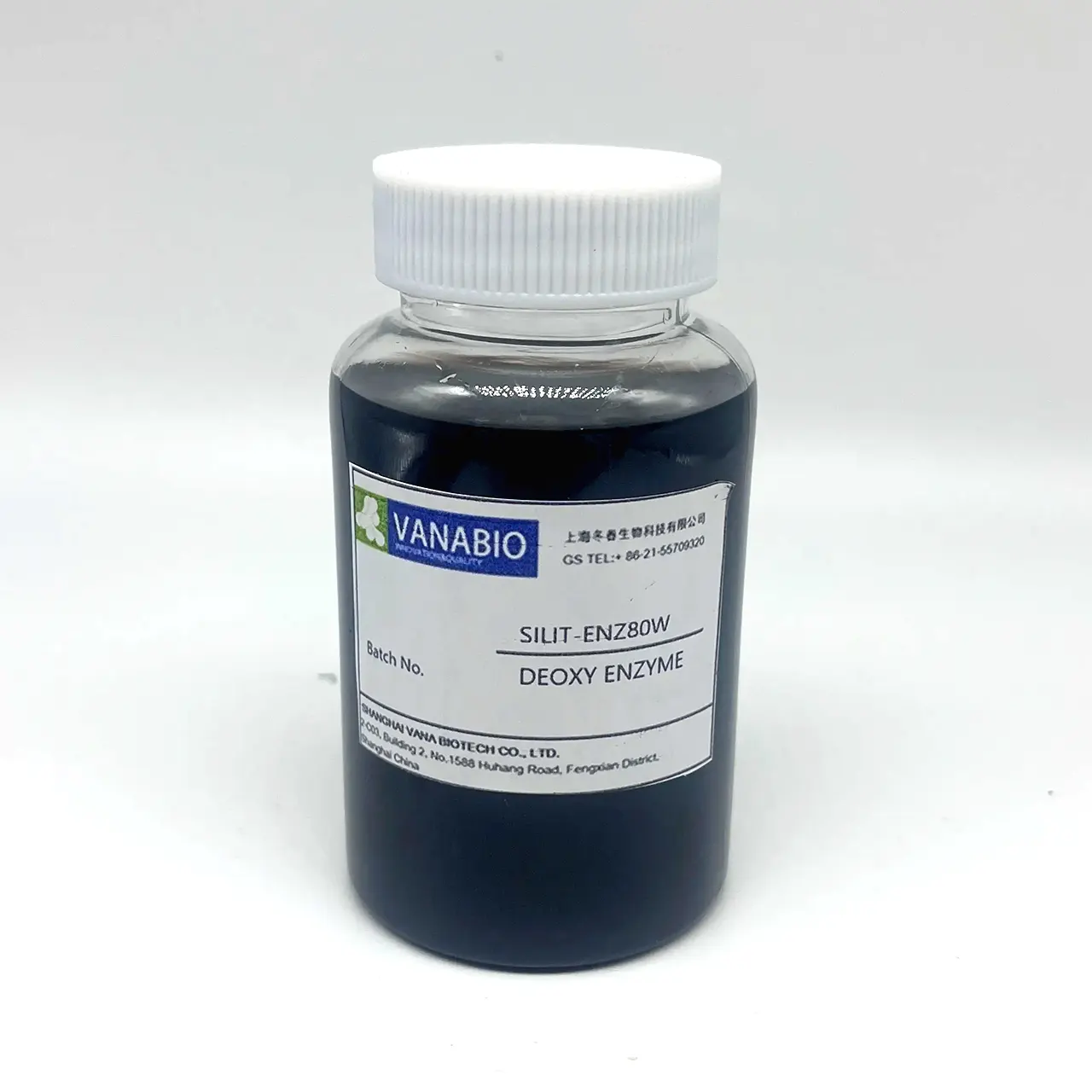

Industrial Implementation Case:

SILIT-ENZ 80W – derived from genetically modified Aspergillus niger strains via deep-tank fermentation – resolves post-bleaching residual peroxide issues that cause irregular dye absorption ("dyeing flower defects").

Peroxide Decomposition Enzymes: Advanced Bleach Neutralization

Deoxygenase enzymes (hydrogen peroxide dismutases) provide essential functions in modern denim bleaching:

- Catalytic Peroxide Elimination

Converts residual H₂O₂ into water and oxygen within minutes

- Oxidative Damage Prevention

Protects cellulose chains during storage intervals

- Process Efficiency Gains

Reduces rinsing cycles by >40% versus traditional chemical neutralization

- Dyeing Defect Elimination

Prevents catalytic discoloration and patchy indigo removal

We specialize in the manufacturing and global distribution of premium textile chemicals:

- Silicone Series: Amino silicone oils, Block silicone polymers, Hydrophilic silicone fluids, and their corresponding emulsion systems

- Performance Enhancers: Wetting & rubbing fastness improvers, Eco-conscious water repellents (Fluorine-free variants, C6, C8 formulations)

- Denim Processing Solutions: ABS indigo removal agents, Specialty enzymes, Spandex fiber protectors, Manganese elimination compounds

Global Market Reach: Exported to major textile hubs including India, Pakistan, Bangladesh, Türkiye, Indonesia, Uzbekistan, and adjacent regions.

Detailed technical specifications available upon inquiry

Contact Us :shanghai Vana Biotech Co., Ltd

📍 Address: Room 203, Building 2, No.1588 Huhang Road, Shanghai, China

🌐 Website:www.vanabio.com

📱 WhatsApp: Avery +86 15056351624

.png)

.png)